When On-Site Training Pays for Itself: A Real-World Jar Testing Example

See how facility-specific, on-site jar testing training helped operators improve chemical dosing decisions and achieve significant annual cost savings using their own water and treatment chemicals.

How Jar Testing saved thousands:

One of the most common challenges we see at small and mid-sized water treatment plants is chemical dosing that feels more reactive than controlled. Operators know something isn’t quite right, but without time, tools, or confidence to troubleshoot, small inefficiencies can quietly turn into big costs.

Recently, WtrWrx Services worked with an Illinois community water treatment plant facing exactly this situation.

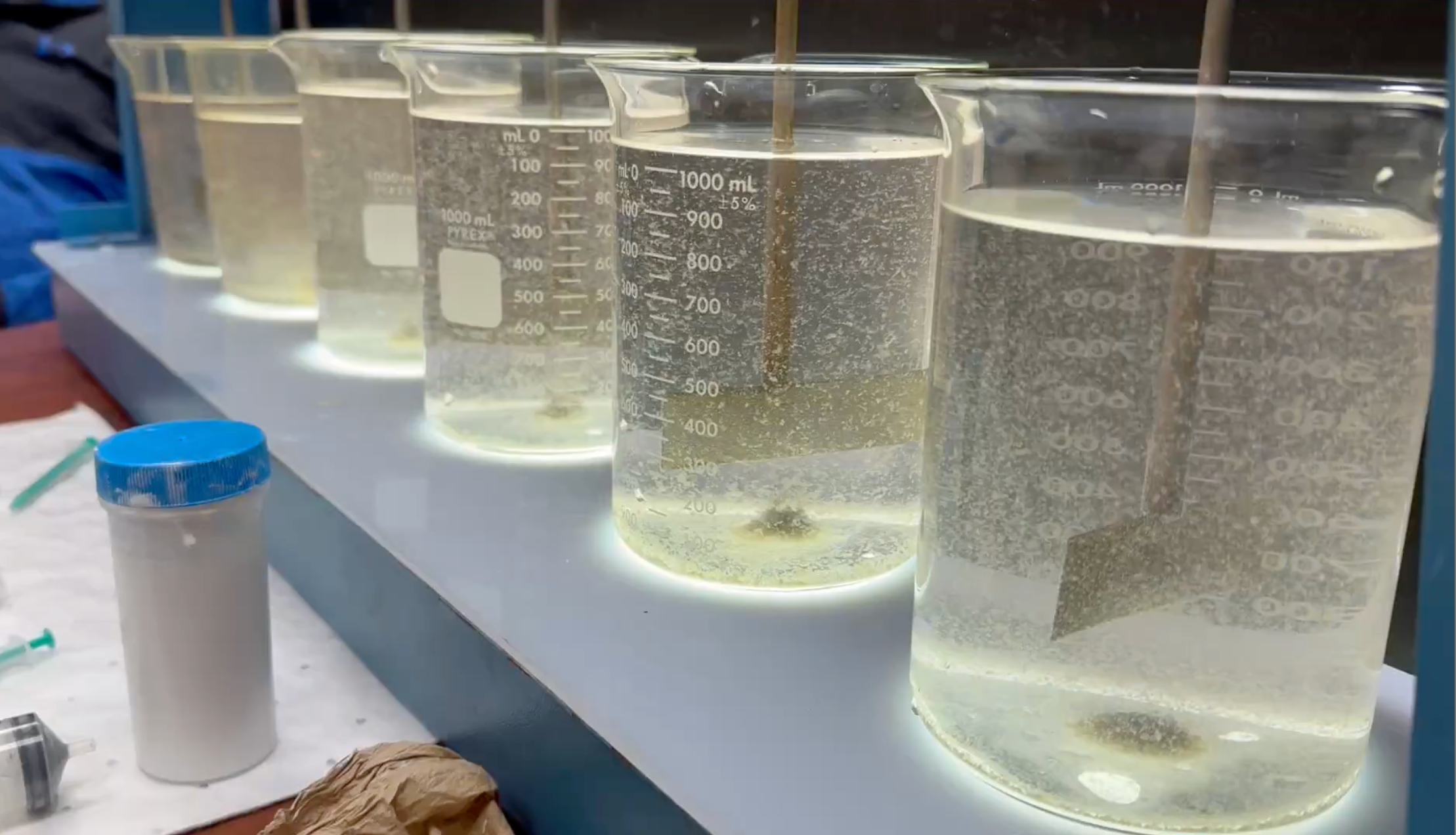

Rather than delivering a classroom-style presentation, we provided on-site, facility-specific training focused on jar testing and chemical dosing, using the plant’s actual source water, treatment chemicals, and equipment.

Training Using the Plant’s Own Water and Chemistry

During the on-site session, operators walked through:

How to properly set up and run jar tests

What to look for when results don’t match expectations

How to troubleshoot dosing issues using visual and performance indicators

How to translate jar test results into confident, real-world dosing adjustments

Because the training was conducted with the facility’s own water and chemicals, the results were immediately relevant. Operators weren’t learning theory—they were solving their own process challenges in real time.

Immediate Results and Long-Term Savings

By the end of the training, the operations team was able to:

Identify inefficiencies in their existing chemical dosing approach

Make informed adjustments based on jar testing results

Establish a repeatable process that they could continue using independently

Those changes led to significant annual chemical cost savings, ultimately more than offsetting the cost of the on-site training itself.

Just as importantly, the operators left with greater confidence in their decision-making and a clearer understanding of how to respond when conditions change.

Why Facility-Specific Training Matters

Every treatment plant is different. Source water quality, seasonal variability, treatment goals, and available resources all play a role in how systems perform.

That’s why on-site training can be so effective:

It uses your water, your chemistry, and your equipment

Operators learn by doing, not just listening

Improvements can be implemented immediately

Benefits extend beyond compliance to cost control and system reliability

Training That Supports Operators and Communities

At WtrWrx Services, our goal is to support operators with practical, field-tested solutions that make daily operations easier and more effective. When operators are empowered to make confident treatment decisions, the entire community benefits—from improved water quality to better use of limited resources.

If your system could benefit from on-site training tailored to your facility and your operators, we’re happy to talk about options that fit your needs.

👉 Learn more about our training services

👉 Contact us to discuss on-site training

Winter Operations Checklist for Water & Wastewater Plants

Winter operations bring more than cold temperatures, including process shifts, dosing challenges, and higher risk of freeze-related issues. This checklist highlights practical steps water and wastewater operators can take to stabilize treatment, protect equipment, and avoid surprise call-outs during winter.

Midwest & Southern Cold Snaps

Winter doesn’t just bring cold temperatures, it brings process shifts, equipment headaches, and higher risk of after-hours problems. Whether your facility is in Illinois, Missouri, Kentucky, Arkansas, or Texas, a few proactive checks can prevent the most common winter issues.

Below is a practical winter checklist operators can use to reduce freeze-ups, stabilize treatment, and avoid surprises.

Protect Freeze-Prone Equipment and Lines

Focus areas:

Exposed piping, sample lines, and small-diameter tubing

Chemical feed lines and day tanks

Pump stations, valve vaults, and meter pits

Outdoor instrumentation and analyzers

Quick wins:

Verify heat trace operation (and label circuits)

Confirm insulation is intact and dry

Add wind protection where possible

Keep enclosure doors sealed and gaskets in good shape

2. Review Chemical Dosing for Cold Weather

Cold water changes reaction rates and can affect chemical performance. Winter is often the time when plants see “drift” — things still work, but not as well.

Check:

Are chemical pumps delivering accurate rates?

Are viscosity changes affecting feed consistency?

Are you seeing changes in turbidity, chlorine demand, alkalinity, or pH stability?

Tip: If you haven’t done a quick dosing verification recently, winter is the time.

3. Watch Biological Performance Closely (Wastewater)

As temperatures drop, biological activity slows. That can show up as:

Higher effluent BOD/TSS

Nitrification stress or ammonia creep

Changes in settleability

Check:

DO setpoints and blower performance

MLSS trends and wasting strategy

Settling and clarifier performance

Any early ammonia or permit-related warning signs

4. Verify Instrumentation and Sampling Reliability

Winter conditions can cause:

Sensor drift

Frozen sample lines

Poor analyzer readings

Check:

Calibrate critical probes (especially if readings feel “off”)

Verify sample line flow and temperature protection

Confirm alarms are working and routed correctly

5. Confirm Emergency Readiness (Before You Need It)

Winter call-outs are tough — especially with holiday staffing and PTO schedules.

Check:

Generator test run + fuel status

Spare parts for known winter failure points

Contact list and escalation plan

Remote access (if you use it) is working

Need Help Winterizing or Stabilizing Treatment?

WtrWrx Services supports water and wastewater operators with on-call and preemptive support — including troubleshooting, dosing adjustments, compliance documentation, and hands-on help when winter issues hit.

If you want another experienced set of eyes on your system this winter, we’re here to help.